Ozone Technology

Ozone kills Organisms/Bacteria and Viruses, leaves no residue or damage but only clean surfaces and air. Other benefits when ozone is used for cleaning or sanitisation fabrics feel softer, food and drinks fresher (often for longer), and even improve drinking water quality for humans, animals, or crops. The list of applications for ozone sanitisation is virtually endless.

Ozone has been scientifically proved to achieve a level of cleanliness that no other machine or service can achieve. See the research information for yourself below.

CONTACT FOR MORE INFOThe Downside to Traditional Technologies Are:

Sanitisation is a manual process and only as good as how thoroughly the surfaces, floors and walls are manually cleaned especially those areas difficult to access

Difficulties in sanitising paper and electronic equipment when cleaning work surfaces

Reliance on hazardous chemicals in the cleaning process

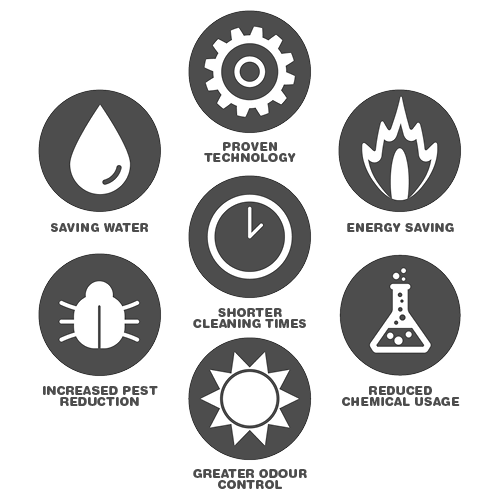

The Benefits of Ozone Technology:

Cleaning and sterilization of any surface accessible to ozone gas or ozonated water without relying on manual labour – accessibility for a cleaner is no longer an issue

Cleaning and sterilization of any surface accessible to ozone gas or ozonated water without relying on manual labour – accessibility for a cleaner is no longer an issue

Ozone gas can clean paper and electronic equipment surfaces as easily as office equipment, walls and floors

Ozone gas can clean paper and electronic equipment surfaces as easily as office equipment, walls and floors

Removes the requirement for hazardous chemicals in the sanitization process

Ozone is 3000 times more effective then chloride.

Ozone has the ability to kill most known bacteria and other common organism – a sample list is shown below.

| BACTERIA | VIRUS |

| Acetobacter | Adenovirus (type 7a) |

| Achromobacter butyri NCI-9404 | Bacteriophage (E.coli) |

| Aeromonas harveyi NC-2 | Coxackie A9, B3, B5 |

| Aeromonas salmonicida NC-1102 | Cryptosporidium |

| Bacillus anthracis | Echovirius 1,5,12 & 29 |

| Bacillus paratyphosus | Encephalomyocarditis |

| Bacillus subtilis | Hepatitis A |

| Clostridium botulinum | HIV |

| Clostridium tetoni | GD V11 Virus |

| Cryptosporidium | Onfectious hepatitis |

| Coliphage | Influenza |

| Corynebacterium diphthriae | Legionella pneumophila |

| Eberthella typhosa | Polio virus (poliomyelitis) 1,2 & 3 |

| Endamoeba histolica | Rotavirus |

| Escherichia coli | Tobacco mosaic |

| Flavorbacterium SP A-3 | Vesicular stomatitis |

| Gluconobacter | FUNGUS & MOLD SPORES |

| Lactobacillus | Aspergillus candidus |

| Leptospira canicola | Aspergillus glaucus (bluish-green) |

| Listeria | Aspergillus niger (black) |

| Megasphaera | Aspergillus terreus, saitoi & oryzac |

| Micrococcus candidus | Botrytis allii |

| Micrococcus caseolyticus KM-15 | Colletotrichum lagenarium |

| Micrococcus spharaeroides | Fusarium oxysporum |

| Mycobacterium leprae | Grotrichum |

| Mycobacterium tuberculosis | Mucor recomosus A & B (white-gray) |

| Neisseria catarrhalis | Mucor piriformis |

| Pectinatus | Oospora lactis (white) |

| Pediococcus | Penicillium cyclopium |

| Phytomonas tumefaciens | Penicillium glaucum |

| Proteus vulgaris | Penicillium roqueforti (green) |

| Pseudomonas Fluorscens (biofilms) | Rhizopus nigricans (black) |

| Pseudomonas putida | Rhizopus stolonifera |

| Salmonella choleraesuis | CYSTS |

| Salmonella enteritidis | Cryptosporidium parvum |

| Salmonella typhimurium | Giardia lamblia |

| Salmonella paratyphi | Giardia muris |

| Sarcina lutea | ALGAE |

| Seratia marcescens | Chlorella vulgaris |

| Shigella dysenteriae | Thamnidium |

| Shigella paradysenteriae | Tricoderma viride |

| Spirllum rubrum | Verticillium albo-atru |

| Staphylococcus albus | Verticillium dahlia |

| Staphylococcus aureus | FUNGAL PATHOGENS |

| Streptococcus ‘C’ | Alternaria solani |

| Streptococcus faecalis | Botrytis cinerea |

| Streptococcus hemolyticus | Fusarium oxysporum |

| Streptococcus lactis | Monilinia fruiticola |

| Streptococcus salivarius | Monilinia laxa |

| Streptococcus viridans | Pythium ultimum |

| Torula rubra | Phytophthora erythroseptica |

| Vibrio alginolyticus & angwillarum | Phytophthora parasitica |

| Vibrio clolarae | Rhizoctonia solani |

| Virrio ichthyodermis NC-407 | Rhizopus stolonifera |

| V. parahaemolyticus | Scierotium rolfsil |

| YEAST | Scierotinia scierotiorum |

| Baker’s yeast Brettanomyces | PROTOZOA |

| Candida albicans-all forms | Paramecium |

| Common yeast cake | Nematode eggs |

| Saccharomyces cerevisiae | Chlorella vulgaris (Algae) |

| Saccharomyces ellipsoideus | All pathogenic and non pathogenic forms of Protozoa |

| Saccharomyces sp. |

Meat Processing

In February 2020 the Food Standards Agency released figures that there are 2.4m food poisoning cases a year in the UK, of which 380,000 are due to norovirus, over double the estimated numbers from a decade ago in 2009.

So why use ozone to clean areas, machinery, vessels etc – quite simply it does the job much more effectively than chlorine, bleach and many other preparations. It will save time, labour and money. Ozone can be used as a gas to disinfect areas or diluted with water, for washing down. Either way we at Hygiene Efficiency have a product that will fit your applications, offering less downtime and a much safer biological environment.

Whatever your processing room looks like Hygiene Efficiency can produce a sanitisation system combining ozone in gaseous and ozone water application. Gaseous systems linked to the ventilation system will deliver low level ozone into the atmosphere well below the safe OEL with the benefits of:

Sanitising hard to reach surfaces such as those at height or awkward to reach

• As the ozone is a gas it can get into the machinery to what would normally be impossible to clean parts.

• Cleans all trolleys or racks which move in an out of the food processing area.

• As ozone is heavier than air it will fall to the ground and continue to clean right into gullies, and drains.

• Is a labour free system so removes human error in not cleaning a 100% of the surfaces 100% of the time.

Applications

Ozone water can be used for any washdown process:

• A chemical free alternative for any clean-in-place protocol as the ozone systems can be used to feed jet washers

• Ozone water systems can be incorporated into any continuous wash/rinse process giving further sanitisation of the food, equipment and conveyor belts.

• With a rotation of knives through a bowl of ozone water they can be kept sanitised whilst maintaining the speed of production.

In a two-stage process Hygiene

In a two-stage process Hygiene Efficiency can keep your storage rooms clean. Firstly, by using ozone water in wash down it will remove bacteria, viruses and moulds from all surfaces without the use of chemicals. Then an ozone machine attached to the ventilation system will deliver low level ozone into the atmosphere well below ozone’s safe OEL eradicating and inhibiting the presence of airborne pathogens.

Odour Control applications

Hygiene Efficiency have experience in producing odour control systems for a variety of different sectors. Ozone is as a natural cleaner and when it interacts with an odour a chemical reaction takes place and the odour harmlessly broken down; the smell is then permanently removed and is not just masked.

Food Product benefits

It is not just the machinery, equipment and surfaces which can be cleaned by ozone but the food products too. There have been several well documented outbreaks of illness throughout the world linked to the consumption of raw fruits and vegetables all of which can be washed with ozone water replacing chlorinated water (the most common wash agent) and removing the issue of residual chlorate levels in the food. Not only will your food products be clean but published research has shown ozone water makes fruit and vegetables a better product.

Food Processing

In February 2020 the Food Standards Agency released figures that there are 2.4m food poisoning cases a year in the UK, of which 380,000 are due to norovirus, over double the estimated numbers from a decade ago in 2009.

So why use ozone to clean areas, machinery, vessels etc – quite simply it does the job much more effectively than chlorine, bleach and many other preparations. It will save time, labour and money. Ozone can be used as a gas to disinfect areas or diluted with water, for washing down. Either way we at Hygiene Efficiency have a product that will fit your applications, offering less downtime and a much safer biological environment.

Whatever your processing room looks like Hygiene Efficiency can produce a sanitisation system combining ozone in gaseous and ozone water application. Gaseous systems linked to the ventilation system will deliver low level ozone into the atmosphere well below the safe OEL with the benefits of:

Sanitising hard to reach surfaces such as those at height or awkward to reach

• As the ozone is a gas it can get into the machinery to what would normally be impossible to clean parts.

• Cleans all trolleys or racks which move in an out of the food processing area.

• As ozone is heavier than air it will fall to the ground and continue to clean right into gullies, and drains.

• Is a labour free system so removes human error in not cleaning a 100% of the surfaces 100% of the time.

Applications

Ozone water can be used for any washdown process:

• A chemical free alternative for any clean-in-place protocol as the ozone systems can be used to feed jet washers

• Ozone water systems can be incorporated into any continuous wash/rinse process giving further sanitisation of the food, equipment and conveyor belts.

• With a rotation of knives though a bowl of ozone water they can be kept sanitised whilst maintaining the speed of production.

Transfer Room applications

Where customers require product movements in / out of clean rooms ozone can be used to provide a suitable sanitisation process. Either by flooding ozone gas into the sealed room which removes human error in not reaching 100% of the surfaces or by using ozone water as a spray wash on non-porous such as trollies and staging.

Storage Room applications

In a two-stage process Hygiene Efficiency can keep your storage rooms clean. Firstly, by using ozone water in wash down it will remove bacteria, viruses and moulds from all surfaces without the need for chemicals. Then an ozone machine attached to the ventilation system will deliver low level ozone into the atmosphere well below the safe OEL for ozone eradicating and inhibiting the presence of airborne pathogens.

Odour Control applications

Hygiene Efficiency have experience in producing odour control systems for a variety of different sectors. Ozone is as a natural cleaner and when it interacts with an odour a chemical reaction takes place and the odour harmlessly broken down; the smell is then permanently removed and is not just masked.

Food Product applications

It is not just the machinery, equipment and surfaces which can be cleaned by ozone but the food products too. There have been several well documented outbreaks of illness throughout the world linked to the consumption of raw fruits and vegetables all of which can be washed with ozone water replacing chlorinated water (the most common wash agent) and removing the issue of residual chlorate levels in the food. Not only will your food products be clean but published research has shown ozone water makes fruit and vegetables a better product.

Wineries

In 2012, we began working with ozone as a sanitiser and Hygiene Efficiency leads the industry in the development of ozone advancements and applications. We have worked closely with its winery clients on the efficacy of ozone in winery sanitation applications becoming the leader in the production of mobile and stationary ozone sanitation systems able to produce systems to meet the needs of any size winery.

The increased use of Ozone in wineries as a sterilisation system is due it’ number of unique properties:-

• Ozone is powerful enough that organisms cannot develop a tolerance to and kills a much broader

spectrum bacteria, fungus and moulds, yeasts, spores, and cysts.

• Ozone is a stand-alone organic sanitiser which simplifies sanitation, is cost effective, safe to use, saves water and energy, and is environmentally friendly.

• Ozone is produced as needed on site, dissipates after use, reverting to oxygen leaving no damage or any residual compounds and minimizes the purchase, storage, mixing and disposal of chemicals.

• Ozone is a cold sanitiser that saves energy, extends barrel flavours, and minimizes bottling line maintenance costs and cool down cycles.

• Ozone was approved by a FDA Expert Panel as GRAS for use as a sanitiser in 1997, by the FDA for use with fruits, vegetables, meat, poultry, etc. in June and under USDA Organic Rule in 2000.

• Ozone unlike halogenated chemicals (i.e. chlorine, iodine, etc.) does not generate TCA precursors or dangerous halogenated hydrocarbon by-products, such as THM’s.

• Ozone destroys objectionable taste and odour causing compounds whilst being pH neutral doesn’t change the acid/alkaline balance.

• The grape coming in from harvest will be totally sanitised before entering your manufacturing process.

• Depend where you are the world, some companies are not able to use chemicals on the grapes for the last three weeks before picking. We have an ozone solution to protect your fruit during this time.

• We are also able to reduce crop loss when planting of vines.

Breweries

In 2012, we began working with ozone as a sanitiser and Hygiene Efficiency leads the industry in the development of new ozone advancements and applications.

Ozone is a stand-alone organic sanitiser which simplifies sanitation, is cost effective, safe to use, saves water and energy, and is proven to be environmentally friendly.

Benefits include

• Clean-in-place cycles reduced by at least 30 minutes versus standard chemical cleaning

• Additional opportunities for water recycling

• Major opportunities for maximising production, reducing operational costs and chemical handling

• Environmentally friendly alternative in terms of mitigating energy and water consumption

• Hygiene Efficiency has worked closely with its brewery clients to become the leader in the production of mobile and stationary ozone sanitation systems and produces systems designed to meet the needs of any size brewery.

• Ozone is produced as needed on site, dissipates after use and minimizes the purchase, storage, mixing and disposal of chemicals.

• As ozone is a cold sanitizer it saves energy, extends barrel flavours, and minimizes bottling line maintenance costs and cool down cycles.

• Ozone kills a much broader spectrum bacteria, fungus and moulds, yeasts, spores and cysts from 10 to 5000 times faster than halogenated chemicals (chlorine, iodine, etc.)

• Ozone was approved by a FDA Expert Panel as GRAS for use as a sanitiser in 1997 and was approved by FDA for use with fruits, vegetables, meat, poultry, etc. in June 2001 (food additive petition). Also in 2000 ozone was approved under USDA Organic Rule.

• Ozone reverts to molecular oxygen, leaving no by-products or residual contaminants and unlike halogenated chemicals (i.e. chlorine, iodine, etc.) does not generate TCA precursors or dangerous halogenated hydrocarbon by-products, such as THM’s.

• Ozone is pH neutral, (does not change the acid/alkaline balance).

Applications

• When used in a tank recirculation mode ozone can save hundreds of litres of water during the tank sanitation process.

• Bottles, Bottling and Can Line Sanitation – Conserving water and energy and qualities and low water use make it an excellent alternative to chemicals, steam and hot water.

• The use of cold ozonated water eliminates the stresses from expansion and contraction of bottling line components created by heat resulting maintaining bottle, bottling and can line sterility..

• Process Piping, Hose, Pump, and Appurtenance (Valve, Clamp, Gasket, etc.) Sanitation – Preventing the transfer of spoilage organisms within the brewery

• Keg, Keg Washer/Racker Sanitation – conserving water and energy whilst maintaining keg sterility make it an excellent alternative to chemicals, steam and hot water for sanitizing kegs without the need for rinses.

• DE Filter and/or Plate & Frame Filter Sanitation – the unique cold sterilisation ability of ozone, combined with its non-contaminating qualities and ease of use, make it an excellent sanitizer for filters.

• Wooden Tank/Barrel Sanitation and Storage – aqueous ozone eliminates and prevents the return of microbial spoilage organisms (i.e. Brettanomyces, Acetobacter, etc.) in wooden tanks and barrels. Plus with no rinsing after the sanitation required it reduces cleaning times and water usage.

• Surface Sanitation – sanitising brewery floors, walls, drains and other surfaces with aqueous ozone reduces microbes (fungi, yeast, and bacteria), maintains a sanitary brewery, and eliminates background odours.

• Air Sanitation and Vector Control – the use of gaseous ozone to control mould, airborne spoilage organisms, odours and some insects is a common practice and had many applications in breweries.

Aircraft Industry

The environment in an aircraft can create the best conditions to allow the growth of bacteria and viruses with, the combination of a large group of people in a contained space, the heating/air conditioning system and the level of humidity. The use of an ozone system to sanitise an aircraft will provide a complete clean free from bacteria, microorganisms, and odours quickly and without the use of harmful chemicals.

In modern aviation the speed of turn-around is another one of the most important issues in the industry. With ozone equipment, the whole water system can be disinfected within half an hour, leaving no taste or smells again without the use of harmful chemicals such as Chlorine.

Ozone Solution

A proven technology that can save you time, money and resources whilst improving your quality and service

How the solution achieves results

• Ozone is created by our machine and either directly fed into the water system or emitted as gas

depending which application the ozone system is carrying out.

• Bespoke protocols are created for your machine by our team depending on your operational requirements

Our solution has been engineered differently from any other Ozone based system. It achieves results through changing the molecules of the water fed into the machine.

How our solution is implemented

• We work with you to define a business case and return on investment for our system

• We review your existing infrastructure, machines and processes in place to understand how you waork at present and the current levels of quality you demand

• We install our machine and work alongside you to produce the right sanitization procedures for your application

• We attend your site as many times as required to yield the benefits we indicated within the agreed business case

Ozone is 150% more powerful disinfect than chlorine and kills up to 3000 times faster

We GUARANTEE

• Against any staff health and safety concerns

•We also recognise that your investment in your business is a substantial one, which is why our tailored solutions use innovative, quality equipment and components that utilise only the best available technology in your industry. This cornerstone of our service assures that your business will perform exactly as intended from day one and for many years to come.

Technical Specifications

• Ozone kills all bacterias known to man

• Ozone levels delivered within system very safe

• Fully health and safety risk compliant

• Ozone test packs to measure ozone levels and air monitors can be supplied with every solution

• Low sound of operation (50 Decibel) similar to a standard pocket washing machine in operation

• Risk assessments available on safety of ozone solutions if required

• Full material safety information provided for each installation

• The machine is classed as a ‘green item’ by the government and so each system is applicable for 19% tax relief upon purchase

• Full training provided with each installation

• Device is mobile and so can be moved or be fixed to a wall/base surface

• Machine dimensions of 100cm by 67 by 95

Ozone Generator

• Connected to mains power by a 13 Amp plug (equivalent as running 100W light bulb)

• Connected to the mains water pipe network only. No need to alter individual machines.

• Works up to 5 bar water pressure.

• Can be used on 22mm pipe up to 2 inch with other systems available for larger pipes

• Safety warning mechanisms built into the system to protect staff in the event of failure

• Bespoke protocols provided within each machine to achieve the increase in yield and reduction in chemical usage

• works on 5 bar water pressure

• Provided with a 1 year warranty but extended warranty option available 3 and 12 month service plans provided from Year 2 onwards. Service included in price for Year 1

Technical Support

Systems implemented with agreed response times to any system issues experienced.

Next to Zero Downtime

System implementation completed within 1-2hr time frame to fit within your business hours and activities